P3

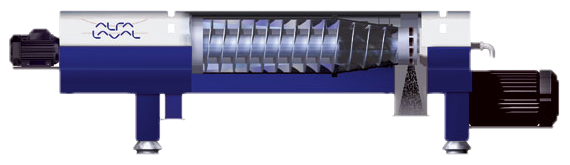

Alfa Laval’s P3 range of decanter centrifuges is built for the toughest applications and is specifically developed for solid-liquid separation in the mining and mineral industry. Every detail has been designed to deal with the harsh conditions found in mining, mineral processing and tailings treatment applications.

Alfa Laval’s P3 decanter is well suited for a wide range of mining and mineral applications such as:

- Tailings treatment

- Recovery of water, chemicals or minerals

- Treatment of slurries with finer particles

- Where dry stacking with stackable solids is required

- Installations where flexibility and movability are required

- Where environmental concerns are important

Alfa Laval P3 heavy-duty decanter centrifuges are built with carefully selected components such as Duplex stainless steel, heavy-duty bearings and a stiff box beam frame. All interior parts of a P3 decanter centrifuge exposed to abrasion are protected by replaceable tungsten carbide tiles to eliminate problems. The feed and outlet zones have been designed for smooth acceleration of the solids to minimize wear and secure an efficient separation process.

The P3 model offers the highest throughput on the market and handles extremely high solids loads. The special deep-pond design in combination with the unique conveyor and the optimized cone angle configuration allows the P3 to handle volumes far beyond the capacity of any other decanter centrifuge. With the P3 decanter you get:

- High cake dryness, producing a stackable cake

- Very high capacity and small installation area

- Fully wear protected throughout the separation process inside the decanter

- Robust design and high reliability

- Lowest power consumption for any mining and mineral decanter

Cómo funciona

Las centrífugas decantadoras P3 de Alfa Laval están diseñadas específicamente para separar los lodos de minería y minerales, los relaves y los lodos en fase sólida y en fase líquida.

La separación se realiza en un recipiente cilíndrico horizontal equipado con un transportador de volutas. El producto es conducido al tazón a través de un tubo de entrada estacionario y luego es acelerado suavemente en un diseño de zona de alimentación de flujo completo. Las fuerzas centrífugas de hasta 3.500 G hacen que los sólidos se acumulen en la superficie interior del depósito.

El transportador gira en la misma dirección que el depósito, pero a una velocidad diferente. Esto mueve los sólidos hacia el extremo cónico del recipiente. Los sólidos salen del tazón a través de las aberturas de descarga de sólidos en la carcasa.

La separación tiene lugar a lo largo de la parte cilíndrica del tazón, y el líquido clarificado sale del tazón al fluir por encima de los diques de placas ajustables hacia la carcasa.